I recently started making shinobue after 15 years of playing this wonderful instrument. I’ve studied many maker’s flutes and researched various kinds of flute making and finally started making my own. So I will share with you my process of making a fue.

So, where do you get the bamboo for making a shinobue? Shino bamboo suitable to make an instrument only grows in certain parts of the world such as Japan and China. There are various suppliers of shino bamboo such as Mejiro Shakuhachi and Shinobue store in Tokyo, Japan which you can purchase raw shino bamboo from.

- Select bamboo

2. Decide what length you want to make.

3. Straighten bamboo if it needs it.

4. Cut to size.

5. Clean out bamboo.

6. Plug top end (node end) with bees wax.

7. Measure 5/8″ from the back of flute (where the wax ends) to the start of the blowing edge.

8. Make centre line where the mouth hole and finger holes will be on.

9. Drill the mouth hole (14 mm long x 11 mm wide).

10. Blow flute to determine basic pitch.

11. Drill finger holes.

12. Fine tune the flute by adjusting size of holes. Spend a few days playing it much to test its limits.

13. Taper ends with file or belt sander.

14. Glue decorative wood cap on top end. Print # of the flute in coloured paint. Sand and polish.

15. Lacquer bore of the flute.

16. Add rattan binding for added aesthetics and crack prevention.

17. Stamp flute with hanko.

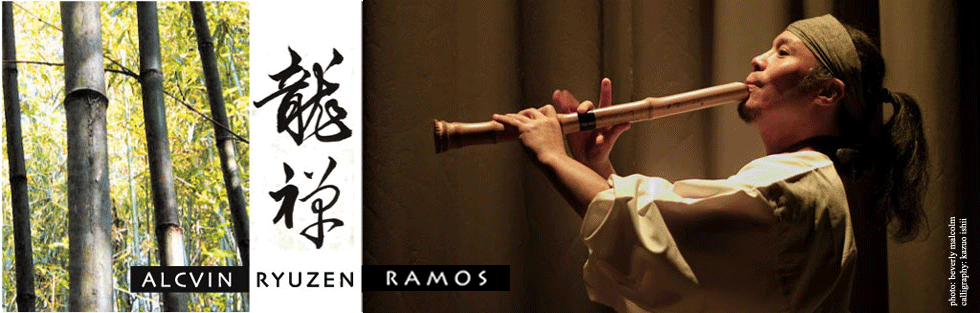

If you are interested in purchasing a fue from me, please contact me at: ryu.zen18@gmail.com and we can talk about what length/key you want.