JINASHI SHAKUHACHI MAKING STEPS:

- Take Tori (Bamboo Harvesting)

- Abura Nuki (Moisture extraction)

- Chikuzai Erabu (choosing the bamboo)

- Tame no Sagyo (bamboo bending)

- Fushi Nuki (node perforation)

- Nekko no Yasurigake (root end formation)

- Kanjiri/ago giri (forming the the ends)

- Zetsumen Kezuru (formation of chin rest)

- Teana akeru (hole drilling)

- Choritsu (tuning)

- Binding

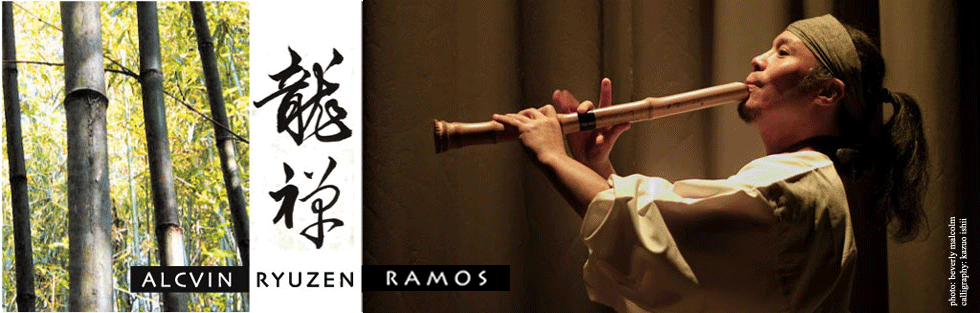

If you’re interested in having Alcvin craft a jnashi shakuhachi flute for you, please email him at: ryu.zen18@gmail.com. Please specify prefered length, bore diameter, pitch, etc.

JIARI SHAKUHACHI MAKING STEPS:

- Chikuzai Erabu: Choosing the bamboo

- Warming bamboo; heat preparation

- Tame no sagyo: straightening bamboo

- Forming the flute shape

- Kanjiri kiri: cutting off the end

- Nakatsugi-kiri: separating the shaft in two

- Gekan fushi nuki: opening the flute by removing the fushi joints

- Hozo hori: mortise joint, connecting insert preparation

- Ware maki: anti-crack reinforcement binding

- Hozo ire: installment of tenon, connecting piece

- Setchaku: bonding of hozo to shakuhachi

- Hozo (connector) installation

- Te-ana shirushi tsuke; marking position of finger holes

- Opening of te ana, finger holes

- Zetsumen giri: mouthpiece shaping cut

- Ago ake: shaping chin piece

- Utaguchi hori: mouthpiece insert preparation

- Utaguchi ire: installation of mouthpiece insert

- 3 types of mouthpieces: Fuke, Kinko, Tozan

- Utaguchi installation

- Naka kesuri: honing the flute shaft

- Seshime: natural, strengthening lacquer applied inside flute

- Ji-oki: application of putty

- Naka tori: honing of flute internals

- Guage test: flute internal check

- Choritsu: tuning

- Naka nuri and uwa nuri: application of lacquer

- Muro kawaki: moisture holding lacquer drying box

- Migaki: polishing with an uzukuri brush

- Fuki urushi: a lacquer application and removal

- Nakatsugi: ornamental gold of silver-lined brass ring to protect and secure connecting piece

- Wakka: the brass ring is polished for strong seal

- Tou-maki: securing of nakatsugi by widening rattan around brass ring

- Shi-age: final applications of lacquer

- Yaki-in: branding with maker’s hanko

- Kabu-mikagi: final polishing of the stock root end

- Kanseihin: finished shakuhachi